Manufacturing the

Finest Moulds

- Home

- / Service /

- Mould Manufacture

TPI-The reliable name in mould manufacturing for precision Injection & compression moulds.

High Grade

Mould Manufacturing

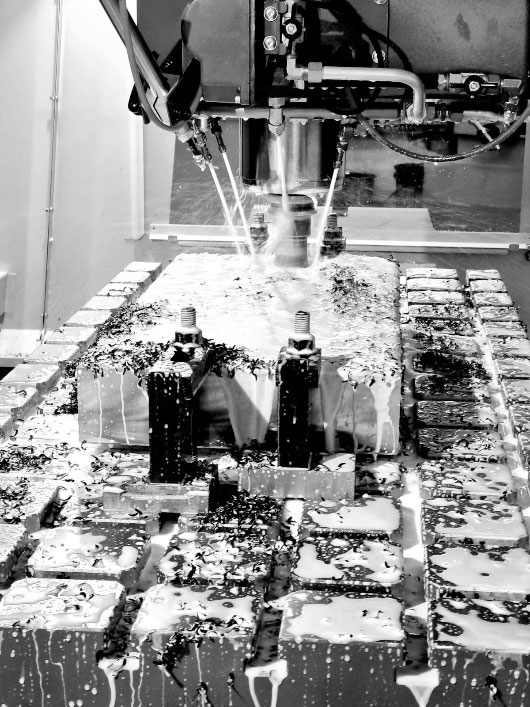

Equipped with industry experience and top-of-the-line tool room machines, TPI has the capability to design and manufacture moulds for thermoplastic injection moulding, thermoset compression moulding and thermoset injection moulding.

TPI’s team of skilled toolmakers, designers and machinists use customer supplied drawings and samples to design, manufacture and maintain moulds with a fully focussed attention to design and quality. TPI’s mould manufacturing assures great value for quality, reliability, affordability and durability.

TPI’s Capabilities

TPI’s strength lies in its ability to adapt and embrace cutting-edge technologies. The prime objective is to create the finest quality plastic moulds that further enhance client satisfaction.

- Usage of modern software to enhance mould manufacturing productivity.

- Support of an in-house design tool room that is equipped with modern machinery.

- Ability to produce engineering-grade moulds that demand tight tolerances and long life.

- Professionally qualified, well-trained workforce to handle operations.

- Design of hot runner and cold runner moulds can be made.

- Ability to handle parts from 5 grams to 2000 grams.

- Advanced CAM/CAD workstation to find value engineering solutions for customers.

- Centralized design and development space to create exceptional tools for our clients.

- Continuous assistance to find solutions that always conform to the client’s requirements.

Manufacturing Infrastructure

Tech Plaastic goes the extra mile to provide the very best in-house manufacturing and moulding amenities. Creating unmatched and cost-effective mould designs are made possible with an infrastructure that is armed with:

CNC EDM Surface Grinding

Vertical Milling Machine

ZW CAD Design Software

Solid Work Design Software

CAE Mould Flow Analysis

High Precision Mould Maker

TPI’s Global Customers have expectations such as high precision, good quality, and low production costs. Most requirements, including dimensional accuracy, conformance to tolerances of finished products and production rate can be met with machine tools incorporating the latest in technology . TPI believes in constant upgradation of machines to meet Customer expectation and keeping in line with this we now have commissioned two new HAAS VMCs.

TPI’s Customers world wide have expectations such as high precision, good quality, and low production costs. Most of such requirements, including dimensional accuracy, conformance to tolerances of finished products and production rate can be met with machine tools incorporating the latest in technology . TPI believes in constant upgradation of machines to meet Customer expectation and keeping in line with this we now have commissioned the HAAS VM3 .

Get in Touch With Our Tooling Engineers

TPI designs & manufactures moulds with ingenuity. Moulds made here can meet tight engineering tolerances and achieve a long life.

Call us TodayReach us

A 21, SIPCOT Industrial Park, Irrungattukottai, Thandalam 55, Kanchipuram Dt. - 602 105, Tamil Nadu, India

call us

+91 9840424173

+91 9840397562

Duns Number

650228575

marketing@techplaastic.com npd@techplaastic.com

Let’s Connect

Get In Touch

TPI’s team of experts are ever ready to answer queries and to take up orders for thermoset injection moulding.